快速搜尋

Petroleum Gauging Tools

Industrial & Tank Truck Equipments

- Air Driven Capstan, 气动絞盘, 氣動絞盤, Pneumatic Capstan

- Air Hoist, Pneumatic Chain Hoist

- Air Pilot Valve 250A

- Aljac Bonding Reel, Hannay Grounding Reel

- Antiluce Fasteners, Truck Parts

- Basket Type Strainers, 籃式過濾器

- Blackmer LGLD2, LGLD3, LGLD4 Liquefied Gas Pumps

- CONTRINEX INDUCTIVE SENSORS DW-AD-501-065E, DW-AD-502-065E, DW-AD-503-065E, DW-AD-504-065E

- CROSBY J-SERIES Direct Spring Pressure Relief Valve, Crosby J-Series PRV

- Dixon 6200 Series Drop Elbow

- Explosion Proof Motors, Explosion Proof Pumps

- Explosion Proof Electric Ventilation Fan, ATEX 防爆風機, Pneumatic Ventilation Fan

- Foot Check Valve

- Full-Circle Swivels SMAC Series, SMAC-112, SMAC-114, SMAC-200, Full Circle Swivels

- Graco Husky Air Operated Diaphragm Pumps

- Industrial Bitmetal Thermometer

- Industrial Hose Products, Gates Longhorn, Premo Flex, Willcox Composite Hose

- KOGANEI Manual Valve 250V, Air Indicator KIL-R

- Laboratory Glass Bottles Brown, Oil Sample glass Bottles, 試劑玻璃瓶, 油樣玻璃瓶

- Limit Switch 1LX7000 Series

- Limit Switch Lever

- OPW 1004D3 API BOTTOM LOADING COUPLER

- OPW 190 High Flow Nozzles

- OPW 7H Automatic Shut-Off Nozzles, OPW 7HB, OPW 11AP, OPW 11BP, OPW 12VW

- OPW API BOTTOM LOADING ADAPTOR

- OPW 68EZR-1010 Reconnectable Breakaway 68EZR-7575

- Overfill Prevention Sensor, CIVASTAR Advanced Overfill Sensor Probe 5650U-7, Scully Connect Tank Truck OverFill Sensor.

- Power Cable, Instrumentation Cable

- PZB 351007 AIR OPERATED CLUTCH UNIT 3.5.1.007

- Presuure Gauge, differential Pressure Gauge Diaphragm Type

- REX Pipe Threading Machines NP50A, REX NP50AV, REX NR50AV

- Rotary Unions 旋轉接頭

- River-Wave Air Operated Diaphragm pump, RV15, RV25, RV50

- Scully 08274 Ground Ball, Scully 08560 Ground Bolt

Flanges, Pipelines & Valves

Sealing, Gasket, 密封圈

Instrument & Parts

Fire Protection Solution

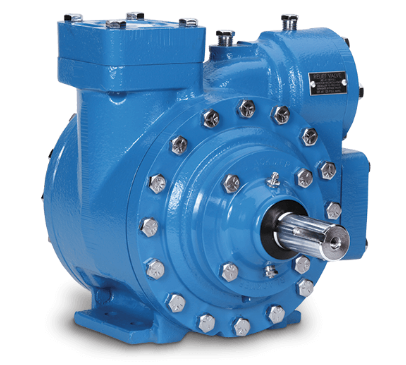

Blackmer LGLD2, LGLD3, LGLD4 Liquefied Gas Pumps

Blackmer Liquefied Gas Pumps & Compressors

Durability / High Efficiency / Quiet Operation / Easy Maintenance

XX"="">XX">

Blackmer offers a full line of liquefied gas pumps and

oil-free gas compressors, designed for maximum performance and reliability. From the smallest cylinder filling operation to

the largest, most sophisticated bulk plant/rail car unloading system, you will find Blackmer pumps and compressors operating throughout the world.

Sliding vane design is ideal for butane, propane, anhydrous ammonia, propellants, refrigerants and similar liquefied gases

Blackmer liquefied gas pumps are widely used for cylinder filling, motor fueling, bulk transfer, vaporizers, and on bobtails and transports.

Utilizing Blackmer’s unique sliding vane design, these positive displacement pumps offer the best combined characteristics of sustained high-level performance, energy efficiency, trouble- free operation, and low maintenance cost.

Pump models are available in 1 to 4-inch port sizes.

All models have ductile iron construction for thermal shock resistance, low friction ball bearings for high efficiency and quiet operation, and threaded lockcollars that prevent end thrust wear

Multi-Purpose Pumps for Bulk Plants, Terminals and Truck Systems

These rugged pumps are ideal for bulk plant service, multiple cylinder filling applications, vaporizers, bobtails and transports.

Single- or double-ended drive shaft models are offered in 2-, 3- and 4-inch port sizes with capacities ranging from 30 to 350 U.S. gpm (114–1,325 L/min). The LGLD2 and LGLD3 models have long been popular for bobtail service because of their double-ended drive shaft arrangement, which allows the pump to be easily positioned for clockwise or counter- clockwise shaft rotation.

All models have an internal relief valve, and a replaceable casing liner and end discs for easy rebuilding of the pumping chamber if ever necessary. In addition, these pumps feature cavitation suppression liners to reduce noise, vibration and wear.

Standard construction materials include Buna-N mechanical seals and Duravanes for handling both LP-gas and anhydrous ammonia.

Maximum differential pressure for the 2- and 3-inch models is 150 psi (10.34 Bar), and 125 psi (8.62 Bar) for the 4-inch models. Ports are offered with NPT tapped companion flanges or weld flanges.

Truck Mounted Drive

Blackmer LGLD2 pumps are often mounted to the chassis of a bobtail, or to a steel pad that is welded to the tank.

The 3- and 4-inch models can be mounted to a transport in a number of different ways, generally near or between the tank landing gear brackets.

Truck mounted pumps are normally driven through a P.T.O. or hydraulic drive system. Refer to Blackmer’s Liquefied Gas Handbook-Bulletin 500-001 for various types of bobtail and transport pump systems.